- Economic optimization or energy conservation.

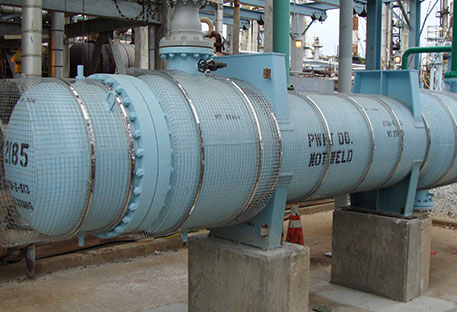

- Limiting & retarding heat gain on cold piping.

- Providing personnel protection.

- Reducing surface condensation.

- Providing process control

- Assisting in personnel comfort in buildings.

- Providing freeze protection.

- Providing noise control or an acoustical barrier.

- Assisting in fire protection.

This is different from the overall uses of insulation as residential & commercial has different goals and the use is much more volumetric. The most obvious and frequently used is for containing heat and economics. Most refinery people don't know that the second largest use is for personnel protection. This is typically 10s of miles of piping in a 150K barrel a day refinery.

- Practical Processing Engineering.

- The Nayer Piping Handbook (used in continuing education seminars and ASME Certification).

- Perry's Chemical Engineering Handbook.

Many don't realize how much insulation is used for personnel protection and how much heat is being held in or what could be cooled. Most busy process engineers just state to IPP or "Insulate for Personnel Protection" in their process specifications since it is usually the standard. Well, the standard is changing and it's profitable for the refinery as well as many other benefits. The process engineers are the ones that can tell you how much you are losing due to a few degrees during the spring, summer, and autumn seasons.